3D Printing Service

action, just like pilots. It’s the matter of life and death and any

mistake can be brutal. This is where 3D Printing comes in and can

guide professionals through their operations.

The Best Medical 3D Printing Services in Toronto

Before 3d printing, engineers had to make sure their medical device is 100% accurate while it was only a digital file.

But real-world experience is not a computer design software environment! So, by adopting 3D Printing, they are now able to 3d print their design and test them in person or by patients. Now they can physically see and feel what is right and wrong. Then they optimize the device design and repeat the print operation until they get the best ever results. Before this, they had to rely on the digital design and cost of optimization and time spent were higher than today. Check the video!

How 3D Printing is a good solution for patients who need specific devices?

Since additive manufacturing can produce on low volumes, patient-specific and costume designs are cost effective. Patients can now enjoy having their unique medical device that is designed for them, for their specific needs and for their unique anatomy. Thanks to 3D Scanning and other body scan methods, we can make prosthetics that is easy to use and functional.

Development process of making medical devices is also shortened. You can achieve at least 50% less time spent on your development. This will lead to less costs and faster ROI.

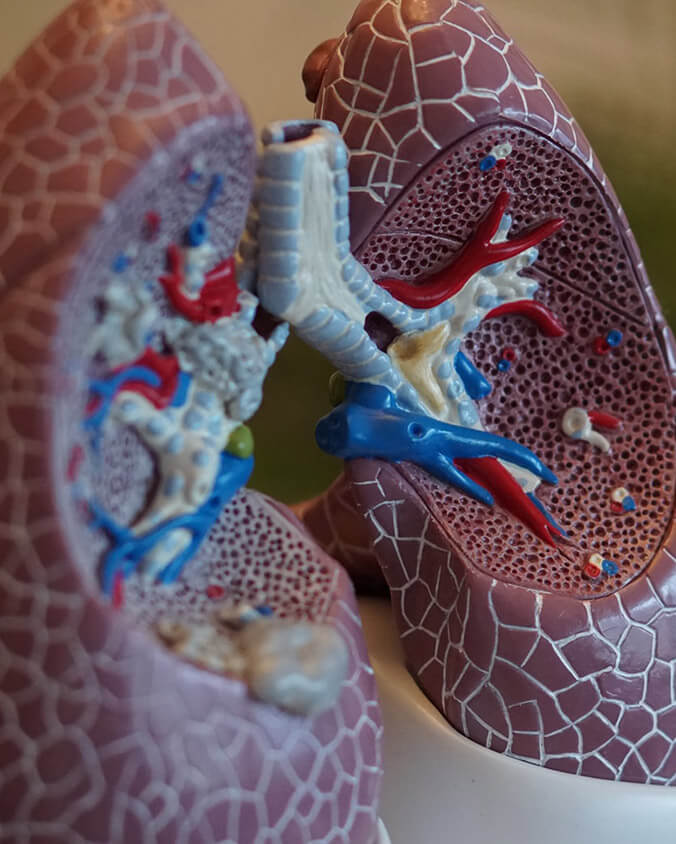

3D Printing boosts medical/surgical models and devices

All doctors and surgeons need to simulate their operation before action, just like pilots. It’s the matter of life and death and any mistake can be brutal. This is where 3D Printing comes in and can guide professionals through their operations. The Stratasys J750 Polyjet 3D Printer is here for medical device makers and surgeons, now available in Toronto, Canada!

How does 3D Printing help manufacture medical devices?

Before adopting additive manufacturing in medical sector, designers and engineers used to prepare designs and manufacture model by conventional methods. It means they had to design a device in CAD files and deliver it to CNC machines. Just like any mass production line. But Additive manufacturing came in let doctors make devices that is optimized and corrected multiple times. This way, medical devices are now more advanced than anytime and they are extremely more efficient. But how is that possible?