The Rise of 3D Printing in Robotics

In recent years, the integration of 3D printing technology in robotics has sparked a revolutionary transformation. It has not only streamlined the manufacturing process but has also opened up a world of new possibilities for robotic applications. In this article, we’ll delve into the remarkable synergy between 3D printing and robotics, exploring the various ways in which this dynamic duo is changing the game.

Rapid Prototyping and Iteration

One of the most significant advantages of 3D printing in robotics is its ability to facilitate rapid prototyping. Traditional manufacturing processes often involve lengthy lead times and high costs. However, with 3D printing, robotic engineers can quickly produce prototypes, allowing them to test and iterate their designs more efficiently. This accelerated development process means that cutting-edge robotic solutions can be brought to market faster than ever before.

Customized Components

Robotic applications often require specialized components tailored to the task at hand. 3D printing enables engineers to design and produce custom parts with unprecedented ease. Whether it’s a gripper optimized for a particular object or a housing perfectly fitted to a unique sensor, 3D printing allows for unparalleled customization. This flexibility ensures that robots can be optimized for a wide range of applications, from manufacturing to healthcare.

Complex Geometries and Lightweight Structures

Robotic systems frequently demand intricate, lightweight structures that are challenging to create using traditional manufacturing methods. 3D printing excels in constructing complex geometries that are both strong and lightweight. This capability is crucial for developing agile and efficient robots, as well as reducing energy consumption and production costs.

The Impact on Robotics

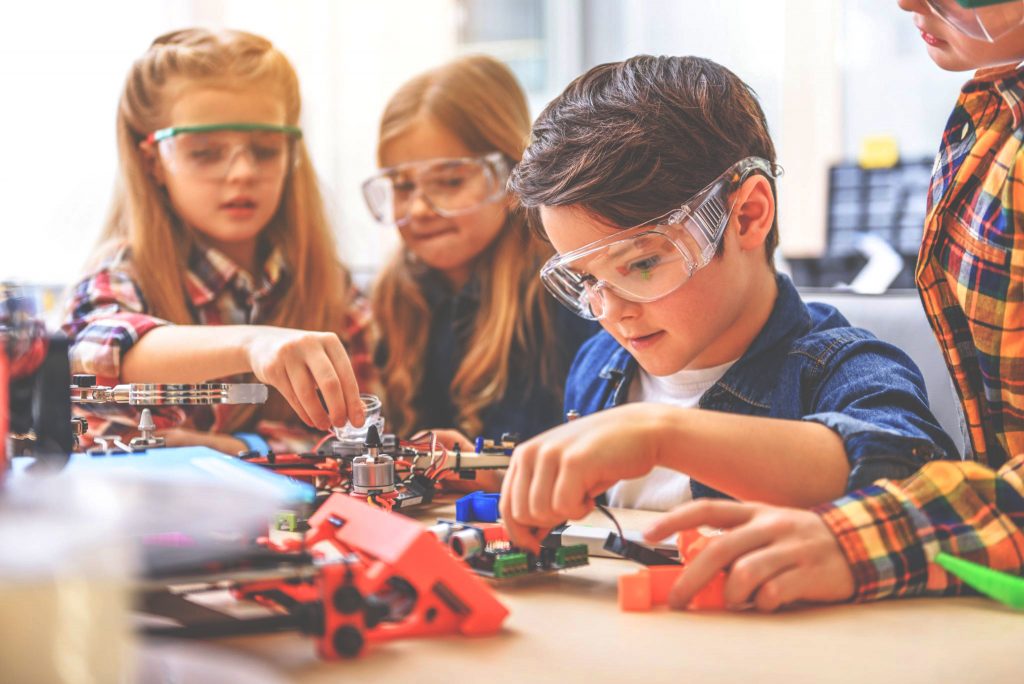

Accessibility and Affordability

3D printing has made cutting-edge robotics more accessible than ever. With lower production costs and greater design freedom, smaller companies and hobbyists can now compete in the robotics arena. This democratization of robotics technology encourages innovation and diversity within the field.

Reduced Environmental Impact

Traditional manufacturing processes can be wasteful, generating excess material and energy consumption. 3D printing is more resource-efficient, as it produces less waste and uses only the material necessary for the job. This sustainability aspect aligns with the increasing demand for eco-friendly solutions in the robotics industry.

The Future of 3D Printing in Robotics

As 3D printing technology continues to advance, its influence on robotics is set to grow. The ability to create complex, lightweight structures, customize components, and reduce production costs will drive innovation in robotics for years to come. This dynamic synergy between 3D printing and robotics will lead to the development of smarter, more efficient robots that can tackle a broader range of tasks.

Conclusion

In conclusion, the integration of 3D printing in robotics represents a pivotal moment in the evolution of these industries. The combination of rapid prototyping, customization, and sustainability not only streamlines the manufacturing process but also expands the horizons of what robotics can achieve. As we move into the future, 3D printing will continue to be a driving force behind the development of more efficient, versatile, and accessible robotic solutions.

3D Printed Parts

We print rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.